POWER PLANT PERFORMANCE OPTIMIZATION

IMPROVE YOUR POWER OUTPUT & HEAT RATE

Turbo Efficiency has a interdisciplinary team that can evaluate, diagnostic and implement solutions that will improve the efficiency and output of the plant under its new operating conditions. During the lifecycle of a power plant there are several events that alter the thermal performance of the plant and its equipment.

For example, over time the plant and its components accumulate degradation or due to different reasons (dispatch, fuel changes, grid limitations, etc.) the plant is not running at baseload as in the original design. These events make the plant to operate out of its design point.

SOLUTIONS

Tune your plant based on its current operating conditions

If a power plant has been operating over 5 years it is very likely that will be running out of its optimum efficiency. Tuning the plant and its main equipment to run efficiency at its current operating conditions allow to improve your output and heat rate without necessarily investing in a full plant upgrade.

Get the most out of your current power plant and make it more competitive.

THERMAL PERFORMANCE AUDIT

Steam Process Audit

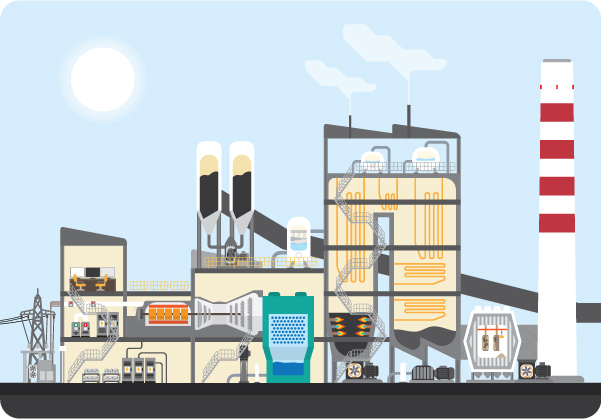

For combined cycles and coal power plants our team can conduct an overall steam cycle audit to review the thermal loads in the process around the boiler or HRSG and in the steam turbine and condensing system. This audit will allow to uncover inefficiencies in the steam cycle and to determine ways to improve the power plant process.

Depending on the complexity of the issue, we can provide a thermal model of the plant to diagnostic with great detail the operation of the plant and ways to improve its overall efficiency. Attemperation flows, by-pass levels, pressure control and vacuum levels can be optimized for different load levels and adjusted for the current degradation of the plant.

This process is recommended prior to a major outage or scheduled maintenance in order to make an action plant to resolve the issues detected.

Our team can correct the mechanical and controls issues detected and implement the necessary changes. Our goal is not only to measure and diagnostic performance issues, but also to correct them.

Controls Audit

To adjust to the current power plant operation, power plants must update their controls settings to take into account the accumulated degradation of the equipment and if the plant is running at reduced capacity.

Our team of control’s and DCS experts can review, advise and if necessary adjust the control settings of the plant.

GAS TURBINE & COMBINED CYCLE TUNING

Gas Turbine Thermal Analysis

During the commissioning the control settings of a gas turbine are adjusted in order to meet the performance, emissions and combustion stability requirements. Not all gas turbines go into this process at site; some the adjustments happen at the plant. However, these settings are calculated based on the conditions of a new and clean turbine. Every year the turbine and its components accumulate degradation. Also, parameters such as fuel composition, load fluctuations and modifications in hardware make the control settings not longer applicable for the current condition of the turbine.

Our team will adjust the control settings of the unit to an optimum level given the new conditions of the turbine.

In order to modify these controls setting an analysis of the gas turbine performance needs to be conducted to establish the current combustion temperature, compressor and turbine efficiency and inlet and outlet conditions.

Combined Cycle Performance Optimization

Our team will work together with the plant personnel to review the original heat balance from the design point and evaluate the current combined cycle operation. From this we will evaluate the current efficiency of the main equipment, the heat losses around the cycle and changes to the operating modes of the plant. Using this information we will tune the control settings of the plant to improve the overall cycle efficiency.

If we conduct a gas turbine performance tuning in a combined cycle, we will evaluate the impact of the gas turbine performance in the overall cycle efficiency and output. Using this information, we will work together to select a set of control settings that improve not only the gas turbine efficiency but the total combined cycle as well.

CUSTOMIZED PERFORMANCE SOLUTIONS

Specific analysis for your performance needs

Power plant operators know better than any other what is happening in their power plant. There might be a specific need to improve the efficiency of a specific system of equipment. However, the plant needs to know the repercussions of any modifications to the rest of the plant.

Turbo Efficiency can help to produce the analysis to ensure any modification can be of benefit to the overall performance. Our team as well can implement some of the modifications and if not, we can point out what are the specific needs of the plant. For example, we have been asked to analyze an addition to the cooling tower system or what will be the consequence from a performance point of view of removing the blades of the last stage in a steam turbine. We can answer all this with accuracy so the plant can plan what is more convenient for the total power plant efficiency.

HOW DOES IT WORK?

POWER PLANT PERFORMANCE OPTIMIZATION

STUDY THE PLANT CONFIGURATION

Analyze the equipment and components installed in the plant. This includes review the mechanical components, controls systems and software installed and the overall plant operation of the plant.

DESIGN THE SPECIFIC SOLUTION(S)

Propose a list of solutions to improve the performance of the plant or equipment around the plant. Each proposed modification will specified the expected benefits in output, heat rate or another power plant performance parameter.

BASELINE PERFORMANCE TEST

Our team will measure the current power plant performance to establish the performance of the plant or the installed power generation equipment. This is important to show the benefits of our power plant performance optimization solutions.

IMPLEMENT THE OPTIMIZATION SOLUTION(S)

We will implement the modifications to the control, hardware and processes to improve the power output and heat rate of the power plant.

EVALUATE THE FINAL PERFORMANCE TEST RESULTS

Once implemented the controls or hardware modifications, we will evaluate the performance of the plant and will evaluate the results.

REQUEST

A

QUOTE

Thank you for your interest.

Please fill out the form to inquire about our services to conduct a performance test.

REQUEST

A

QUOTE

Thank you for your interest.

Please fill out the form to inquire about our services to conduct a performance test.

![Combined-Cycle-Sketch-[Converted]](https://b1913480.smushcdn.com/1913480/wp-content/uploads/2021/04/Combined-Cycle-Sketch-Converted.jpg?lossy=0&strip=1&webp=1)